Shipping containers are an essential part of international shipping, serving as sturdy, reliable carriers for goods across the globe. But have you ever wondered how these containers are made? The process is intricate and involves various stages of construction to ensure durability and functionality. In this blog, we will take a deep dive into the shipping container manufacturing process, exploring each step in detail.

How Shipping Containers Are Made?

Shipping containers are crucial for global shipping, helping transport goods worldwide. But how they’re made? Here’s a detailed look at the process and the different steps involved in ensuring these containers are strong and reliable.

Step 1: Wall Panels

The first step in the shipping container manufacturing process involves creating the wall panels. The primary material used is corrugated corten steel, known for its strength and flexibility. Large steel sheets are cut and shaped into corrugated panels, which form the side walls of the container. These panels are essential for the structural integrity of the container, helping to distribute the load evenly and resist deformation.

Step 2: Floor Frame

Next, we focus on the floor frame, which plays a key role because it supports all the weight inside the container. The floor frame is built using strong steel beams, which are welded to I beams for extra stability.

On top of this frame, a steel floor is laid down to provide a solid base. In some cases, wooden flooring is added on top of the steel floor to give even more strength and make the floor easier to maintain. This setup ensures that the container can safely carry heavy loads without breaking or getting damaged, making it strong and reliable for shipping.

Step 3: Roof Panel

Once the wall panels and the floor frame are ready, the next step is to add the roof panel. The roof is typically made from the same corrugated corten steel as the walls, providing a uniform strength across the container. The roof panels are carefully fitted and welded to the top of the container structure, ensuring a watertight seal and overall structural cohesion.

Step 4: Assembling the Container

Once the wall panels, roof panel, and floor frame are ready, the next step is to put the container together. The wall panels and roof are welded to the floor frame to make a strong, sturdy structure. Careful welding is done to make sure all the joints are secure and the container is airtight.

During this stage, the doors and corner posts are installed. The doors get door handles and locking mechanisms to make sure they can be securely closed. These features are important for the container’s security and functionality ensuring it stays properly sealed and safe while being transported.

Step 5: Adding Protective Elements

The final step in making a shipping container is adding protective coatings to make it last longer and handle tough weather. First, weathering steel is used, which helps the container resist rust and wear. On top of this, additional layers of protection are added to ensure it stays strong over time.

Rubber seals are fitted around the doors to keep water from getting inside, making sure the container stays weather-tight. The side walls and floor frame are then primed and painted. Priming and painting provide an extra layer of protection against rust and corrosion. This finishing touch helps the container stay in great condition and be ready to handle harsh weather conditions during transit.

By adding these layers of protection, the container is prepared to carry heavy loads safely and reliably, no matter what the weather throws at it.

Conclusion

In summary, making shipping containers involves a detailed process to ensure they can handle global shipping needs. It starts with creating the wall panels from corrugated steel, building a strong floor frame, and adding the roof panel. Each step is crucial for making sure the container is strong and reliable.

The wall panels, roof, and floor frame are welded together to create a solid structure. During assembly, key features like doors, door handles, and locking mechanisms are added to keep the container secure and functional. Finally, protective coatings, including weathering steel, rubber seals, and a fresh coat of paint, are applied to make the container durable and ready for tough weather.

Understanding this process helps us appreciate the effort that goes into making these important tools for shipping. Shipping containers are built to last, safely transporting goods across the globe and standing up to challenging conditions.

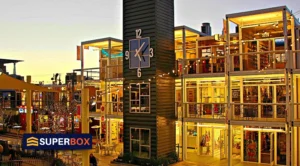

Discover Top-Quality Shipping Containers at SuperBox!

At SuperBox, we offer a variety of top-quality containers designed to last. We’re committed to providing products that meet your needs and go beyond your expectations.

Whether you need a container for shipping, storage, or any other use, we have the perfect option for you. Our team is dedicated to making sure you’re satisfied and will assist you throughout the entire process.

Explore our range to find the right container for your needs. For more information or if you have any questions, call us at 1-866-696-9269. We’re here to help and look forward to assisting you!